|

|

– Thick

plasticard or Masonite hardboard

– 1/4" balsa wood sticks

– 22-gauge picture-hanging

wire

– 26-gauge floral wire

– Epoxy modeling putty (green

stuff)

– Miscellaneous cool bitz

for wreckage

– Coarse and fine sand mixed

– White (PVA) glue and super

glue

– A large, old brush and a paper

cup

– Pencil and steel ruler

– Clippers, hobby knife,

and cutting surface |

|

Breaking through razor wire is an unpleasant experience

that forces you to make your way through sharpened

metal wiring while ducking incoming fire. Razor

wire is invaluable as a defensive measure it

denies the enemy easy movement. In short, it buys

a defender valuable seconds to pump a few more

rounds into the enemy before close combat begins! We made the stretch of razor wire

above with common materials available

at any craft store along with some various bitz

that you'll likely have in your bitz box. With a little time and effort, you too will have

plenty of lovely razor wire.

Before starting, you'll

need to gather some supplies and tools to build

your razor wire. Don't worry if you are missing

a few things, because you can always try to

improvise.

|

|

|

|

|

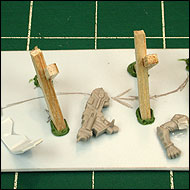

First, you'll

need to cut out a 6" rectangular

section from your base material. The

base can be any width, but 2" should

do nicely. Since you can have up to

six razor wire sections in a scenario,

cut out six bases – you might

as well make 'em all right now.

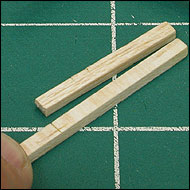

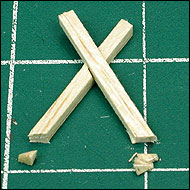

Razor

wire is supported by a bunch of wooden struts that keep the wire in

place on the battlefield – time to make these crossbeams. Measure and

cut out about a 1.25" length of the balsa stick. Use this length as

your template and cut out another of equal length (you don't have to be

too precise). Repeat this until you have 12 separate 1.25" sticks.

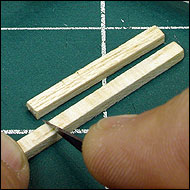

Now, grab two

small sticks. Make two diagonal, parallel

slashes across the width of a single

stick an inch up from the base. Make

the cuts through about half the depth

of the wood, but not completely through

the stick.

|

|

|

|

|

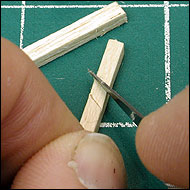

Next, slide

your blade into one of the slashes and

carve out the wood chunk between them.

You should now have a notch into which

the other stick can fit snugly. Place

a dab of white glue in the notch and

insert the other stick to make your

crossbeam.

Once you've made

six supports from the 12 sticks and

glued them together, it is time to cut

them so they'll stand upright and level

(sort of). All you have to do is cut

a triangular bit off the bottom to make

the crossbeam sit level. Check out the

images above to see how to do it. Repeat

this procedure until you have a healthy

pile of wooden "X" supports

ready to be affixed to the base.

|

|

|

|

|

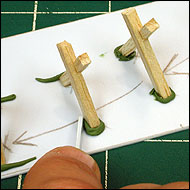

Now, it's time

place all the supports on the base.

Although it seems like a good idea to

just plain glue 'em down, it's not.

Sure, we'll be applying glue, but more

support is necessary. Enter epoxy putty.

Green stuff along with super glue makes

for an extremely tough bond that will

help keep your crossbeams from breaking

off during gameplay.

First, plot out

how you want the supports arranged on

the base. We drew a curved line on our

plasticard base. Once you've decided

on the general layout, place a blob

of super glue on the foot of each crossbeam

and stick it in place on the base. Do

this for each "X" and wait

for the glue to dry. While you wait,

grab the epoxy putty and mix up a fresh

batch. Roll it into a thin line with

the thickness of a paper clip.

|

|

|

|

|

| Now, assuming the glue is dry, break

off smaller sections of your line of putty

and place them against each and every

foot of an "X" that meets the

base. Use an extra bit of plasticard,

a paperclip, or a sculpting tool to wrap

the thin line of putty around each foot.

Once each foot is encircled, use your

sculpting tool and press in the green

stuff to completely seal each foot. While

the putty dries, add super glue to the

green stuff to form the super bond we

mentioned before.

Now is the time

to place battlefield rubble onto your

bases before we cover it with sand .

Use old guns, arms, weapon bitz, cut

up plasticard, vehicle bitz, and any

other detritus you have on hand. Once

these bitz dry, texture the base with

a coat of white glue followed by a mix

of fine and coarse sand. Paint the razor

wire patch as you see fit and set it

aside for now.

|

|

|

|

|

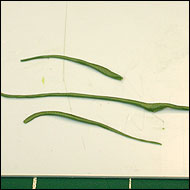

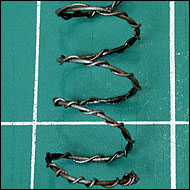

Gather up your

22-gauge wire (thick), 26-gauge wire

(thin), clippers, and super glue. You

can find both types of wire at your

local hardware or craft store.

First,

cut off a 22" length of the 22-guage

wire. Straighten it out so it'll be

a bit easier to work with. Now, wrap

the thinner, 26-gauge wire around one

end of the 22-gauge wire. Make a sort

of knot by going around and around the

wire a couple of times. Then, place

a drop of super glue on this knotted

area to secure it. This glued knot will

make the next steps much, much easier.

With the glue

dry, begin twisting the 26-gauge wire

(while it is still on the spool) around

the thicker, 22-gauge wire in a helix

pattern. Continue going round and round

until you get to the end of the 22-gauge

wire. Try and keep your coils fairly

close together. Once you've wrapped

the thinner wire all the way to the

end of the thicker 22 gauge wire, wrap

a knot with the wiring and seal it with

some super glue like you did when you

started wrapping.

|

|

|

|

|

Dig

up a thick pen, marker, or other cylindrical object that's about 1/2"

thick. Wrap your length of twisted wiring around the object until you

can't wrap any more and then slide it off. This process will give you a

good bundle of curved razor wire. Place this aside and repeat for any

other razor wire patches you plan on making. Quickly paint the razor

wire before moving on.

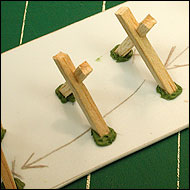

Attach one end

of the razor wire to the first crossbeam

in the line. Try to place this first

point of contact in the area where the

two sticks meet in the center of the

"X". Use a single dot of super

glue and patiently wait for it to dry.

Since the wire is probably coiled together

tightly, stretch out the razor wire

a bit so that it is as long as the base.

Carefully fit

the razor wire to the center of each

support crossbeam. It's a good idea

to lay the entire length of wire across

the base before you begin gluing. This

way, if there is a problem further down

the line, you can correct it now. Don't

be afraid to bend the wire a bit if

necessary. In fact, you will have to

do this in a few spots for the wire

to sit nicely. Once the razor wire is

strung to your liking, finish with a

drop of super glue at each point that

the wire meets with the support struts.

|

|

|

|

|

|